Sanding, sanding, and more sanding

So I have all the panels and pie pieces printed with the exception of the very top panel. I started sanding. From research online, if you plan on hand sanding, you have an enormous amount of work ahead of you. I was lucky enough to have a received a Dremel Multi-Max oscillating tool from my wife for Christmas a year or two ago, so I have been using that.

So I have all the panels and pie pieces printed with the exception of the very top panel. I started sanding. From research online, if you plan on hand sanding, you have an enormous amount of work ahead of you. I was lucky enough to have a received a Dremel Multi-Max oscillating tool from my wife for Christmas a year or two ago, so I have been using that.

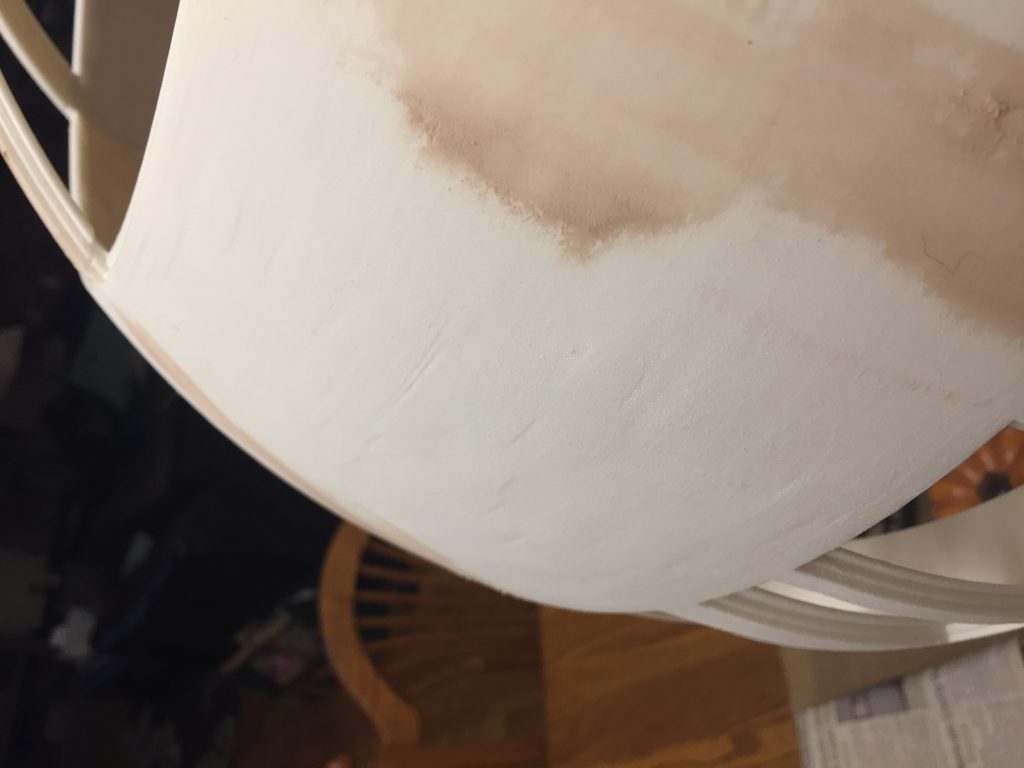

I started with 60 grit sand paper. This thing worked great. I was able to sand most of the layer lines and imperfections out. I planned on using Bondo automotive filler to fill the imperfections that were not easily sanded down. I sanded as much as I could before using the Bondo. As you can see, I filled the seams and any other spots I found.

The Bondo that I purchased was a two part filler. I found that it hardened much faster than I expected, so if you’re going to use this method, plan on working fast. I sanded everything again and inspected my work.

It wasn’t too bad, but I still found areas that needed attention. As I said, working with the two part Bondo was a challenge. I purchased a tube of Bondo Glazing and Spot putty. This appears to be the exact same stuff as the two part Bondo, without having to mix hardener in with the material. I spent some time putting on a second round. I really spread it on the rings, hoping for a good result.

So I’ll continue sanding and sanding and sanding some more…